Quality is the connecting thread across teams, processes, technology, and products.

Quality management is one of those concepts that every company claims to master, yet few truly understand at its core. In a world where ISO certificates, compliance audits, and framed policies often decorate the walls of corporate offices and factory entrances, it is easy to believe that these symbols represent genuine quality. But the truth is simple: certifications may provide structure, yet they are never enough on their own.

In reality, every company must design its own quality management system (QMS), one that fits its processes, its people, its technology, and its customers. There is no single recipe that works for everyone. Instead, there are timeless principles: well-defined processes, strict adherence to those processes, and a culture where attention to detail is not optional but essential.

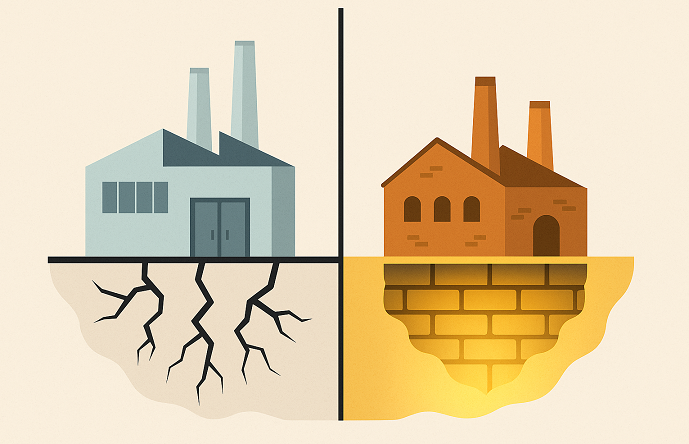

Over the years, one of the clearest contrasts I have noticed is how different factories present themselves compared to how their systems actually perform.

On one side, you find modern, state-of-the-art facilities that look flawless both inside and out. Their equipment shines, their production lines appear organized, and their lobbies are lined with certificates like ISO 9001, sustainability awards, and safety compliance plaques. At first glance, these factories seem untouchable. And in some cases this image is supported by an equally strong Quality Management System. But not necessarily in all cases. When you look deeper, ask questions, observe processes closely, and test traceability, you may discover weaknesses: a surprisingly fragile QMS, with gaps and risks that the polished exterior cannot hide.

On the other side, there are older, less glamorous factories. Their walls may be worn, their layouts outdated, and they may not display rows of certifications at the entrance. At first sight, you might underestimate them. But as you observe their processes and interact with their teams, something different emerges: a disciplined, well-constructed quality management system, with people who take responsibility and follow procedures rigorously. These factories may not impress with appearances, but they win with substance.

A modern look is not proof of strong quality. Some modest factories run solid systems with responsible teams.

The lesson here is simple: quality is not about how things look, it is about how things work.

It would be impossible to talk about quality management without mentioning Toyota. The company revolutionized the world with the Toyota Production System (TPS) and the principle of Kaizen, or continuous improvement. These ideas reshaped not just automotive manufacturing, but industries as diverse as healthcare, software development, and retail.

For decades, Toyota has been held up as the ultimate model of quality and efficiency. And yet, even this global benchmark has faced serious setbacks. In recent years, Toyota has issued major recalls involving airbags, fuel pumps, braking systems, and steering columns, problems that affected millions of vehicles worldwide.

This does not diminish Toyota’s legacy, but it is a powerful reminder: even the best systems can fail if they are not constantly sustained by vigilance, leadership, and daily discipline. TPS and Kaizen are brilliant frameworks, but they cannot replace the responsibility of leaders and teams to live those principles in practice.

So, what makes the difference between a fragile system and a strong one? Not certificates, not slogans, not posters on the wall. The true foundation of quality is people: leaders who are competent, specialists who understand the details, and employees who are engaged and accountable.

Great leaders do more than approve policies. They understand the technological flow of their processes and know where risks can appear. They ensure that every step is traceable and documented so nothing slips through the cracks. They invest in training and skill development not just for compliance, but to empower teams to think proactively and solve problems at the root. They build a culture of responsibility, where quality is not delegated to a department but is everyone’s job.

Quality is people-driven. Leaders and specialists give life to systems and standards.

Without this human element, even the strongest frameworks can become hollow. With it, even modest organizations can achieve excellence.

From my own experience in industries like apparel manufacturing, where one supplier may work simultaneously with multiple brands across different regions, I have seen how challenging it can be to manage expectations. Each client comes with their own requirements, documentation, and standards.

And yet, the one principle that ensures success is consistency. The internal standard of the same high quality must always remain in place, whether you are producing for a luxury label or a mass-market retailer. Because at the end of the day, while brands differ, the definition of quality does not. It means the customer receives a product they can trust, one that fulfills its promise.

There are many ways to illustrate this point.

This is the essence of consistency in quality management: the same high quality standard should not be reserved only for luxury products, it should be the baseline for every product.

As I explain in my book Manufacturing Excellence and Quality Management in Sustainable Fashion Apparel, factories working with multiple clients must build their own internal systems of excellence. The same high quality standard is not just possible, it is essential.

Certifications like ISO 9001 are valuable. They provide structure, they signal credibility, and they create a common language for quality management across industries. But they should never be confused with the actual work of quality.

A certificate might open the door to new clients or markets, but it will not prevent a defect if teams lack training, if processes are poorly documented, or if leaders are disengaged. Real quality comes from what happens day after day on the factory floor or in the service process, not from the framed document at the entrance.

The journey of Toyota shows both the heights that quality management can reach and the risks of complacency. The contrast between shiny, certificate-filled factories with weak systems and modest-looking factories with strong practices reminds us that true quality is often invisible to the eye but always visible in the results.

Every company should shape its own QMS, tailored to its needs, grounded in universal principles, and brought to life by leaders and teams who care. Because in the end, quality is not a label or a certificate.

Quality is a promise to the customer. And keeping that promise requires systems, discipline, and above all, people.

← Back to homepage