Product Recalls Are Climbing. Why Isn’t Quality Keeping Up With Technology?

Factories today run with high-resolution cameras, robots, and algorithms that can see defects no human could. On paper, quality should be soaring. In practice, recall notices keep arriving, often from brands everyone recognizes. The data confirms an upward trend, and the reasons are more practical than mysterious. The real issue is not a shortage of tools, but how they are applied. Quality is built in the quiet details: turning designs into stable processes, keeping changes under control, and acting quickly when data shows drift. When those touchpoints slip, even the smartest lines let defects escape. The way forward is straightforward and demanding at the same time: clear standards, simple checks that always run, and leaders who spend time where the product is made. Do that consistently and the promise of modern manufacturing shows up where it matters most, in safe, reliable products and fewer recall headlines.

The numbers that matter

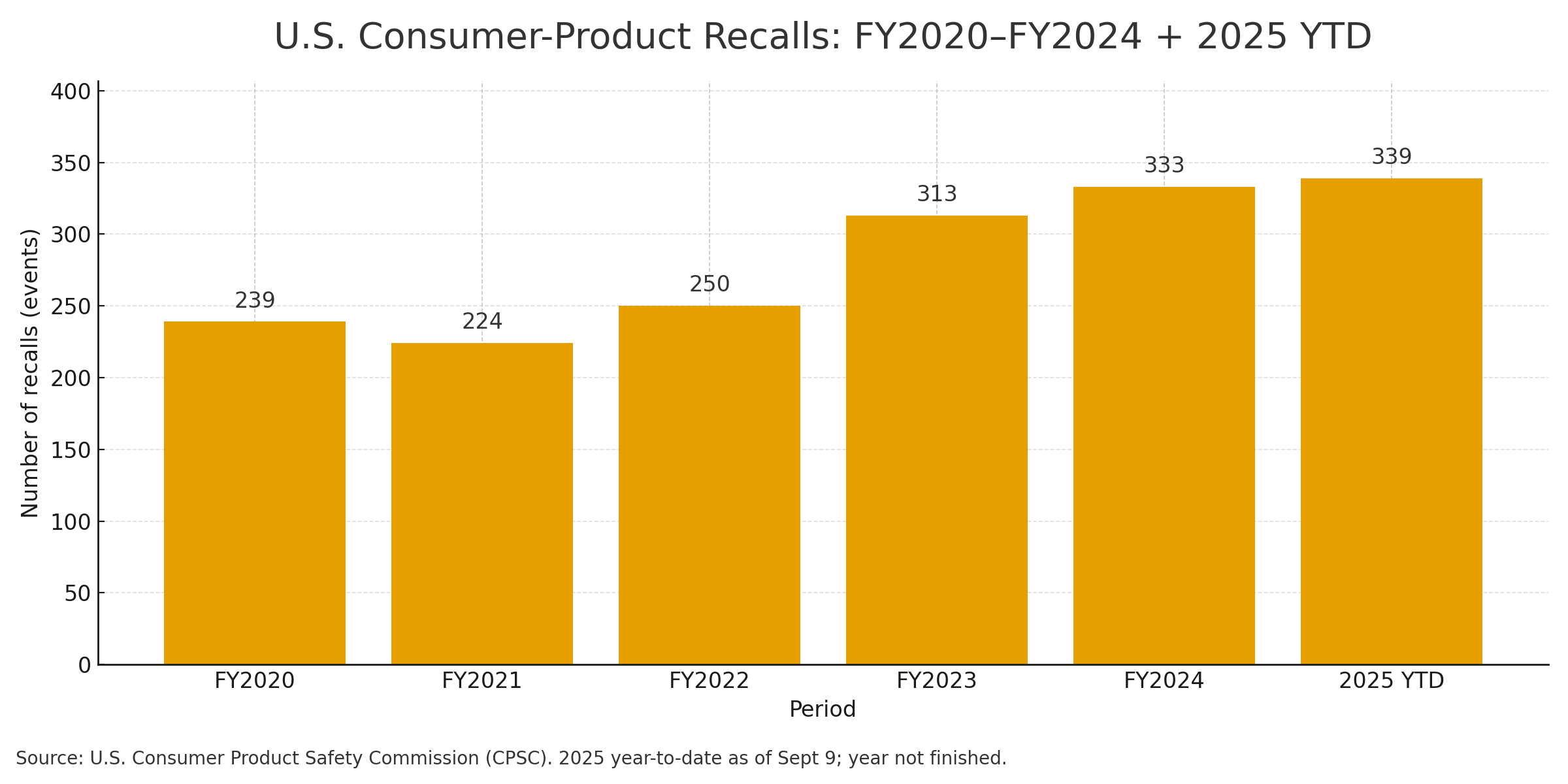

In the United States, the U.S. Consumer Product Safety Commission reports 250 recalls in fiscal year 2022, 313 in fiscal year 2023, and 333 in fiscal year 2024. This is an increase of about one third in two years. CPSC Agency Annual and Financial Reports.

2025 is already higher. By September 9, 2025, CPSC postings show 339 consumer-product recall notices, which is already above the 333 recorded in all of 2024, and the current year is not finished.

Across the Atlantic, the European Commission’s Safety Gate, the EU rapid alert system for dangerous non-food products, logged 4,137 alerts in 2024, the highest since the system launched in 2003.

If we look at harm and not only at recall counts, the National Safety Council, using the CPSC injury surveillance system, estimates 15.1 million U.S. emergency-department visits in 2024 linked to consumer products.

Why technology alone has not solved quality

Machine learning really shines on simple, one-part products. When the item is a single piece and does not require assembly, such as molded components, printed parts, castings, or other one-piece products, computer-vision models work in controlled light, with stable geometry and repeatable surfaces. In these conditions, detection accuracy can approach near perfection for the defects the model is trained to see.

Assemblies are different. The moment a product needs assembly, variation multiplies. Part stack-ups, torque sequences, adhesives, fastener alignment, cable routing, and even packaging can create risks that cameras may not flag reliably. Here, skilled people still matter. Process engineers, quality technicians, and line leaders catch patterns that do not look like the training data and make the judgment calls that keep customers safe.

Remote oversight helps but cannot do everything. Video audits and fixed cameras were vital during and after Covid. Regulators themselves note that remote inspections are useful, yet they do not fully replace on-site checks for tactile, process-sensitive work.

A case study that makes the numbers real: lithium-ion batteries in micromobility

CPSC staff documented 233 U.S. deaths associated with e-bikes, e-scooters, and hoverboards from 2017 to 2022, rising from 5 in 2017 to 76 in 2022.

New York City shows how policy and enforcement can move outcomes. The Fire Department of New York reported 18 battery-related deaths in 2023 and 6 in 2024, a drop of 67 percent after the city tightened rules and pursued uncertified batteries.

The lesson is simple. Technology lowers risk when suppliers, standards, and enforcement work together, and when users know how to charge and store safely.

Not Enough Experts Behind Quality

The technology stack is advancing fast. The talent pipeline is not. Deloitte and The Manufacturing Institute estimate that U.S. manufacturing will need about 3.8 million additional employees between 2024 and 2033, and up to 1.9 million jobs could go unfilled if the skills gap is not closed. These roles include quality engineers, supplier-quality leaders, reliability specialists, and controls and data talent.

The same research points to what works. Partnerships with vocational schools and universities, modern apprenticeships, paid co-ops, and micro-credentials aligned to real plant needs. In 2025, the U.S. Department of Labor announced funding to expand Registered Apprenticeships across states and territories, which helps but needs scale.

Hiring the right people matters. Hire for fit to the line, not just for titles. Audition skills on real defects or changeovers. Put technical thinkers in quality leadership. Financial literacy is useful, but for technical roles, technical judgment protects customers.

What keeps going wrong and how to fix it

Supply chains change faster than oversight. Multi-tier networks and quick substitutions create hidden drift.

Action: require approval before material, tooling, or process changes ship; do risk-based incoming inspection; and push for lot-level traceability with data you can actually audit.

New tech, old playbooks. Teams install cameras and models, but leave control plans and FMEAs static.

Action: connect inspection data to capability and maintenance plans. Update risks, not only first-pass yield.

Under-resourced quality teams. When headcount is thin, sampling plans slip and temporary deviations become normal.

Action: hire and grow quality engineering, supplier-quality, and reliability roles. Rotate engineers and data scientists onto the line, not only into dashboards.

Design for assembly gets skipped. Tolerances stack, fixtures drift, torque tools age.

Action: enforce design-for-assembly gates, add poka-yoke features that make wrong assembly impossible, and verify station capability under worst-case conditions.

Field learning arrives too late. Reviews and forums surface failure patterns in days.

Action: treat them as an early-warning system and run short, focused containment and root-cause sprints before small problems become recalls.

Where machine learning shines, and where people must lead

Use machine learning and computer vision as the authority for one-part products and stable processes. They catch surface and dimensional defects at speed, with consistency that humans cannot match. Put skilled people in charge of assemblies and system behaviors like thermal performance, sealing, vibration, and electromagnetic compatibility. The best results come from a hybrid system where machines do the high-volume screening and experts handle the gray areas.

Sharing my experience

I have worked across industries and seen many kinds of challenges. What made the difference every time was spending enough time on the production lines. On day one I define critical defects with the team and enforce a zero tolerance policy on critical defects, with a clear goal of zero recalls kpi. I extend the same rules to suppliers, verify changes before shipment, and validate fixes on the line, not only in reports. This hands-on approach, together with a living quality management system, has delivered the results that matter: safe products and no recalls.

I have also met role-fit issues, including at well-known manufacturers with vertical integration. Some people in quality leadership were strong at reporting and finance, yet less comfortable with technical details. When I asked a technical question, they often invited a production technician to answer, or we had to pause to align on terminology. This is not a criticism of individuals. It is a reminder that quality leadership is a technical job. The fix is practical: spend time on the line, build a shared technical vocabulary, coach leaders to read processes the way products fail, and prove every corrective action at the station until the risk is truly gone.

The takeaway

The trend is real. U.S. recall notices climbed from 250 to 313 to 333, the EU logged a record 4,137 alerts in 2024, and 2025 is already above 2024 with months to go. Technology did not fail. Operating models and talent pipelines fell behind. Quality improves when organizations blend strong people, instrumented processes, disciplined suppliers, and smart use of machine learning. That mix keeps customers safe and keeps brands out of the recall headlines.

← Back to homepage